Presezzi Extrusion is able to realize all the machinery after the press in order to be able to manage all the phases of production of the finished extruded product.

LEAD OUT TABLE WITH COOLING SYSTEM

- Strong steel structure.

- Tilting rolls made with aluminium case and coated by a Kevlar surface.

- Independent movement up/down of the rolls is made by means pneumatic cylinder or movable cams.

- No foundation works.

- Cooling system under the rolls by means axial fans or centrifugal fans with cooling ducts.

- Fixed / Movable cooling system above the table rollway.

- Automatic raising rollers for the containing of the profile.

RUN OUT TABLE WITH COOLING SYSTEM

- Strong steel structure.

- Idle or motorized rolls.

- No foundation works.

- Cooling system under the rolls by means axial fans or centrifugal fans with cooling ducts.

- Fixed / Movable cooling system above the table rollway.

- Automatic raising rollers for the containing of the profile.

FIRST SET OF BELTS

- Composed by fixed and movable belts.

- Cooling system under the belts driven by frequency converter.

- No foundation works.

- Special quick-change belts system.

- Walking way for maintenance.

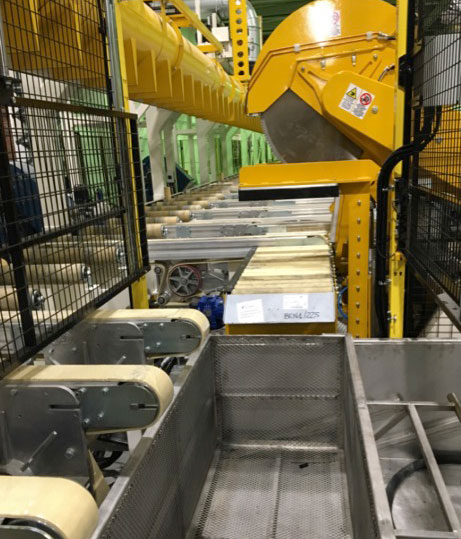

SAMPLE SAW MACHINE

- The saw is installed between the belts of the first set.

- Motorized rollway to drop the cutted pieces.

- Proper chips collector.

- Tank for samples or heads of the profiles.

- Possibility to work in completely automatic mode.

STRETCHER MACHINE

- Finger type or stretcher with de-twist stretching system.

- Semi and Full automatic operation mode.

- Cameras for automatic operations.

- Sensor to detect the profile.

- Upper/lower jaws with pneumatic movements.

- Dedicated hydraulic power unit.

SECOND SET OF BELTS AND ROLLWAY TO FINISHING CUT

- Composed by fixed belts.

- No foundation works.

- Main body of the rolls in steel.

- Surface of the rolls covered with PVC or adiprene anti scratching and antistatic material.

- Up/Down movement of the rollway with pneumatic or hydraulic system.

FINISHING SAW MACHINE

- Composed by steel welded base frame.

- Movements of the clamps by pneumatic cylinder.

- Idle or motorized rolls.

- Vulcanized rollers to avoid damages and keep the area cleaned.

- Proper blade lubrication system.

- Chips suction device with collecting piping ventilator and cyclone.

- Possibility to remove tails and heads of the profiles in semi-automatic way.

- Double saw configuration system for manage short layers of profiles.

CUT TO LENGHT TABLE WITH EVACUATION BELTS

- Different solutions for lighter or heavier profiles.

- Motorized rollway driven by motors with frequency converter.

- Pneumatic Up/Down movement.

- Motorized gauge device driven by a motor with frequency converter.

- Profile cleaning system composed by a blowing system that allow to blow the chips inside the allow profiles (they will be recollected at the saw).

- Evacuation belts to evacuate layer of profiles from the table.